Low operating costs despite low concentrations

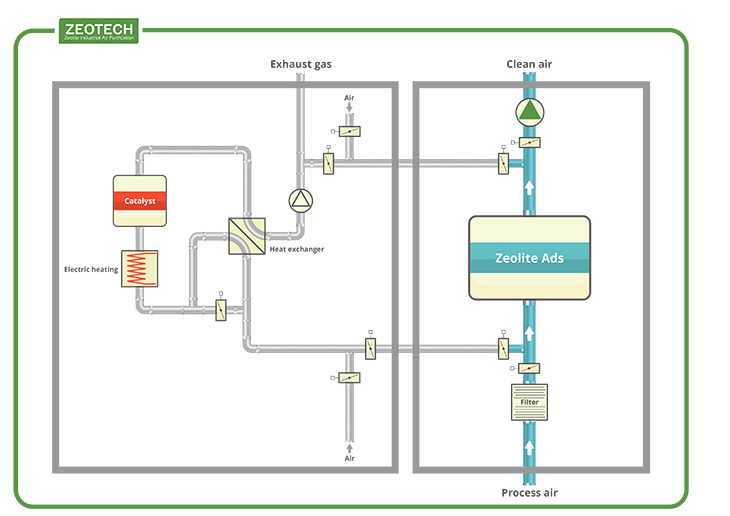

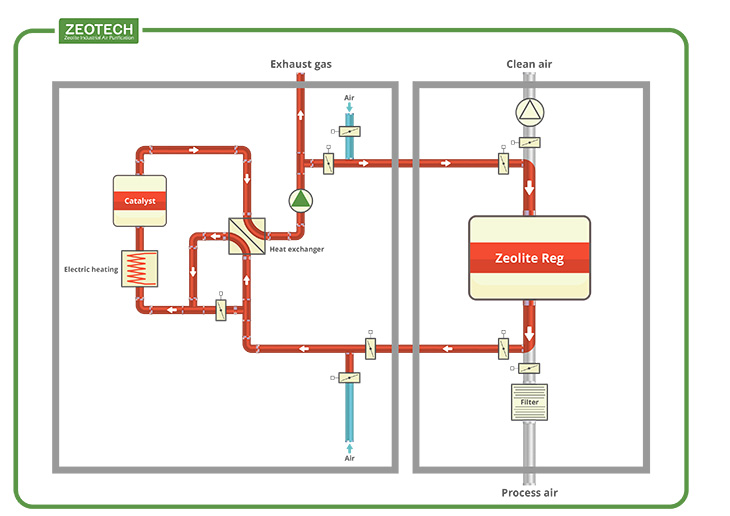

Fixed Zeolite bed for VOC emission

Our fixed zeolite bed for VOC emissions is ideal for the coating and rubber businesses where the concentrations of VOCs usually are low, but can at times be very high. This requires a purification solution that can economically manage uneven VOC concentrations.

+25 years lifespan of our zeolite bed for VOC

Thanks to its crystalline pore system and its resistance to high temperatures, zeolite can always be completely regenerated, giving the systems a very long service life.

Low operating costs

Because you can collects VOCs over a long period of time, regeneration is infrequent – which is cost-effective.

Purifies high and low concentrations

Our system is very flexible and capable of handling low concentrations of VOCs in combination with very high concentrations.

We also offer a ozone catalyst for eliminate ozone in production processes.