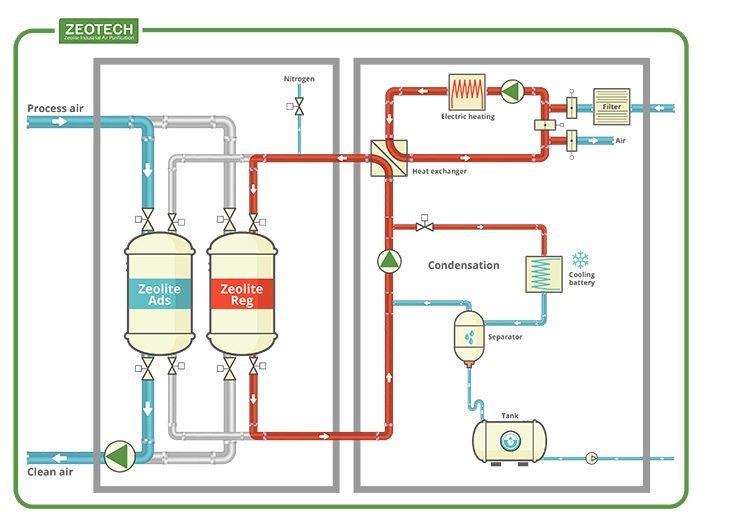

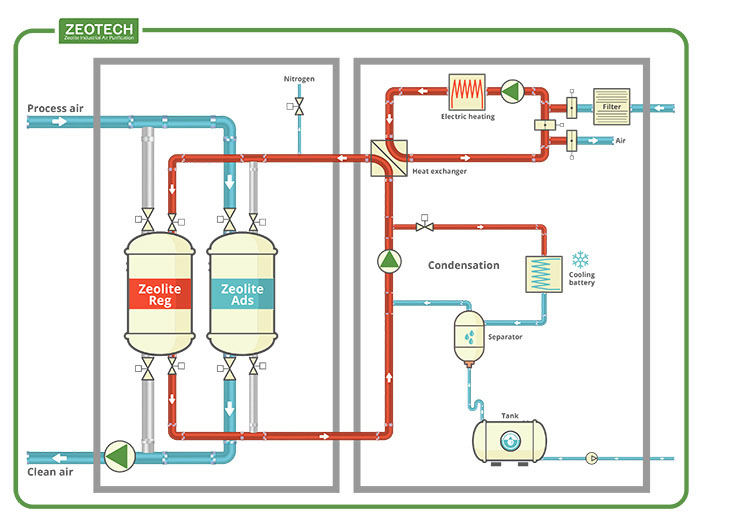

FIXED ZEOLITE BED WITH CONDENSATION

Recycle VOCs from your emissions

There is an increased interest to recycle VOCs in areas such as the chemical and pharmaceutical industries. Our solution helps you stay sustanable and cost effective.

Why Recycle VOCs?

One of the reasons is that the process air may contain chlorinated hydrocarbons, which can create unwanted residual products upon incineration. Another reason is that the amount of VOCs can be high enough to make it financially beneficial to recycle them.

Cost effective

By recycling VOC, the material can be resold to third parties or reused in in your own production. .

Sustainable to recycle VOCs

By recycling the VOCs, you are helping to reduce the consumption of finite natural resources since VOCs are primarily made from crude oil.

We also offer a ozone catalyst for eliminate ozone in production processes.