The zeolite rotor is a wheel made of a fiberglass matrix impregnated with a layer of zeolite.

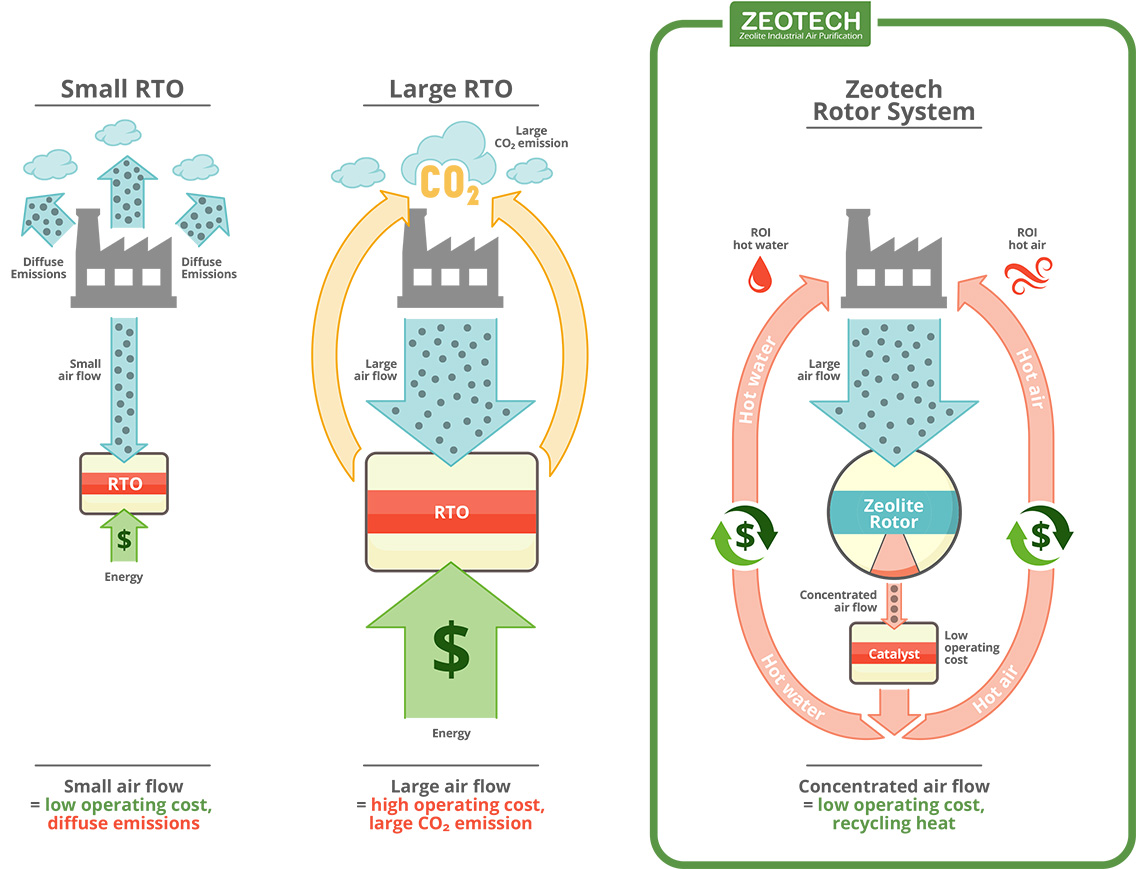

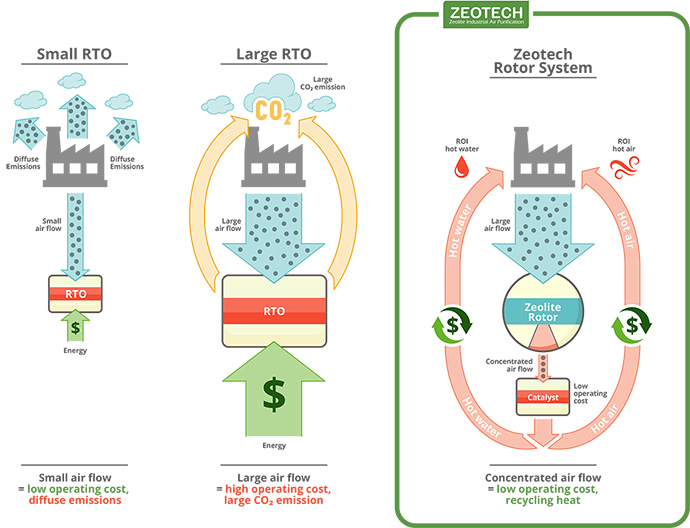

The rotor housing is designed so that the wheel is divided into separate sectors. The VOC-rich process airflow travels through the largest sector (approx. 75% of the surface), where the VOCs are adsorbed by the zeolite. When the wheel rotates slowly (1-3 rph), the zeolite with VOCs enters the next sector, known as the regeneration sector.

A hot airflow travels in the opposite direction to the process airflow, and heat up the zeolite so that the VOCs follow along in the air stream.

The regeneration flow is much smaller than the process airflow, and the concentration becomes 10–25 times higher. As a result, a smaller incineration system can be used for the destruction of the VOCs.

In the third sector, the rotor is cooled to prepare it for absorption when it enters the large sector again. The outbound cooling airflow passes through a heat exchanger, where it is heated further and used as regeneration flow.

The concentrated air is the directed to a catalyst for incineration. Catalytic recuperative incineration is preferable due to its ability to handle large variations in concentration and airflow, in addition to having short start and stop times.